Vinyltrimethoxysilane (PROSILANE™ SC-6110):

Vinyltrimethoxysilane (PROSILANE™ SC-6110):

By Silsource

Published : 04/10/2025

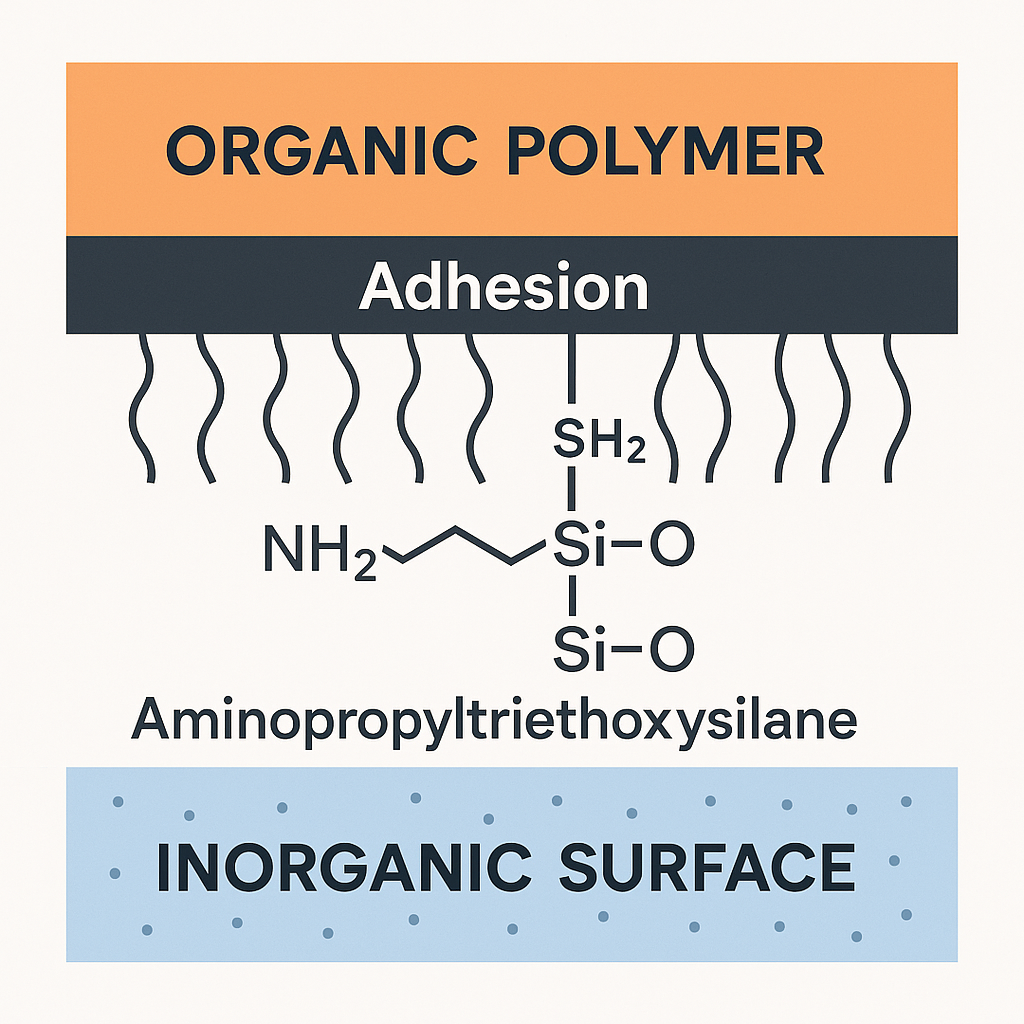

Vinyltrimethoxysilane (PROSILANE™ SC-6110) is a high-value organofunctional silane used by formulators to boost adhesion, weatherability, and mechanical performance across coatings, adhesives, sealants, plastics, and wire & cable applications. Its vinyl group enables co-polymerization with unsaturated polymers, while the methoxy groups hydrolyze to silanols that bond strongly to inorganic surfaces such as glass, metals, and mineral fillers. That dual reactivity is why PROSILANE™ SC-6110 is a go-to choice for manufacturers who need durable interfaces and reliable moisture-cure crosslinking.

What Is Vinyltrimethoxysilane (VTMS)?

VTMS is a silane coupling agent containing a reactive vinyl functionality and three hydrolyzable methoxy groups. In the presence of moisture, the methoxy groups convert to silanols that can condense to siloxane bonds on hydroxylated surfaces (glass, silica, metal oxides). Meanwhile, the vinyl group can participate in polymerization or grafting reactions with compatible resin systems. The result is a durable “molecular bridge” between inorganic substrates and organic polymers—improving interfacial strength, moisture resistance, and long-term performance.

Key Applications of PROSILANE™ SC-6110

- Crosslinking of Polyethylene (PE/XLPE): VTMS is widely used to graft onto polyethylene chains and subsequently crosslink via moisture cure. In wire & cable insulation and jacketing, this chemistry improves heat resistance, mechanical strength, and electrical properties while supporting long service life.

- Adhesives & Sealants: In moisture-curing and silicone/hybrid systems, PROSILANE™ SC-6110 acts as an adhesion promoter that strengthens bonds to glass, metals, concrete, ceramics, and mineral substrates. It helps maintain adhesion after water or temperature cycling.

- Coatings & Primers: As an additive or primer component, VTMS enhances wet and dry adhesion, improves corrosion and humidity resistance, and supports better film integrity on inorganic surfaces.

- Surface Treatment of Fillers & Pigments: Treating silica, glass fibers, and mineral fillers with VTMS improves dispersion and interfacial bonding in composites and thermoplastics, often yielding higher tensile strength, modulus, and dimensional stability.

- Construction & Industrial: Sealants, protective coatings, and flooring systems benefit from VTMS’s moisture-cure durability and robust substrate adhesion in high-traffic or high-humidity environments.

Performance Advantages for Formulators

- Adhesion & Interfacial Strength: Creates durable chemical bonds at the substrate interface for better peel and shear performance.

- Moisture-Cure Durability: Siloxane crosslinks resist humidity, water immersion, and freeze–thaw cycling.

- Weatherability & Chemical Resistance: Improved resistance to UV, solvents, and corrosive environments extends coating and sealant life.

- Mechanical Property Gains: Enhanced tensile strength, modulus, abrasion resistance, and dimensional stability in reinforced plastics and composites.

- Processing Efficiency: Multifunctional behavior can reduce the need for multiple additives or extra primer steps, simplifying manufacturing.

How VTMS Adds Value in Modern Supply Chains

Supply chains today prioritize resilience, quality, and total cost of ownership. VTMS contributes on all three fronts:

- Fewer Failures, Longer Intervals: By strengthening interfaces and resisting moisture/UV attacks, VTMS helps products last longer in the field, reducing warranty exposure and replacement cycles.

- Streamlined Formulations: When a single ingredient can both promote adhesion and enable moisture-cure crosslinking, formulators can trim SKUs, simplify processes, and reduce overall cost.

- Consistent Global Performance: Durable performance across climates and substrates improves product reliability for global OEMs and contractors.

- Sustainability Alignment: Longer-lived materials reduce waste and embodied energy associated with maintenance and re-manufacture.

Industries That Depend on Vinyltrimethoxysilane

- Wire & Cable: XLPE insulation and jacketing where thermal stability and dielectric performance are critical.

- Automotive: Structural adhesives, seam sealers, and under-the-hood plastics that must tolerate heat and fluids.

- Construction: Weather-resistant sealants, primers, and protective coatings for glass, metal, and masonry.

- Industrial & Marine: Anti-corrosion coatings and durable composite parts for harsh environments.

- Electronics: Adhesion promotion and moisture defense in encapsulants and conformal coatings.

Formulation Tips (General Guidance)

- Hydrolysis/Condensation: Control moisture exposure and pH to guide silane hydrolysis and condensation; overly rapid hydrolysis can lead to premature gelation.

- Substrate Prep: Clean, dry, and lightly activated surfaces (where appropriate) maximize coupling efficiency.

- Dosage Optimization: Typical use levels are low; overdosing can reduce compatibility or increase viscosity without added benefit. Validate via ladder studies.

- Filler Treatments: Pre-treating fillers with VTMS can improve dispersion and reduce compound viscosity, leading to smoother processing.

Why Source VTMS from Silsource

Silsource combines reliable supply with technical support tailored to silicone and silane chemistry. On our platform you’ll find fast access to SDS/TDS and product expertise, plus the ELEMENT ai chatbot for on-demand assistance with application questions and formulation compatibility—so your team can move from evaluation to production with confidence.

Explore the Product

View specifications, documentation, and request a quote here: PROSILANE™ SC-6110 — Vinyltrimethoxysilane